The new normal – digital clothing labels

The use of new technologies, such as QR codes, has poised the US to transform the way product data is shared across the value chain. This alongside growing demand for product digitization is enabling scalable solutions for transparency, traceability and more.

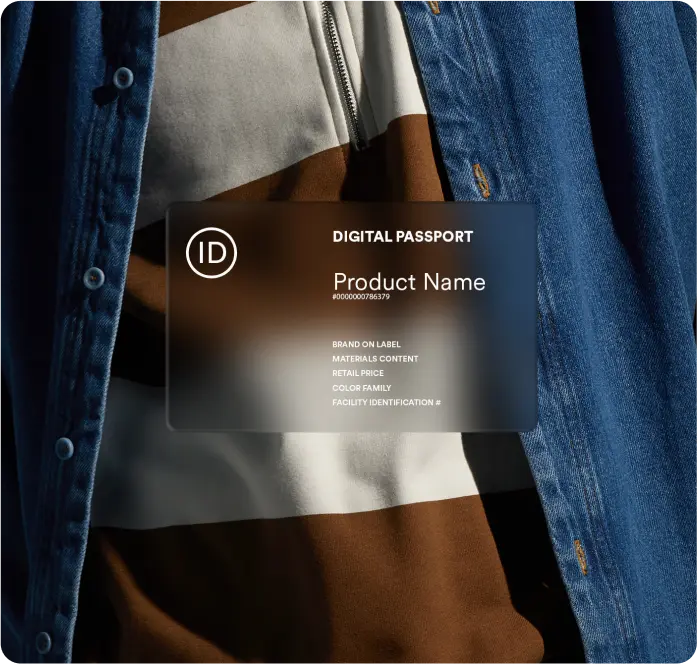

Increasing focus has been placed on Europe to lead the revolution of apparel industry regulations in the name of transparency and circularity. Forthcoming Digital Product Passport (DPP) legislation is one key innovation that policymakers hope will enable measures for a more sustainable apparel industry.

According to the EU’s Strategy for Sustainable and Circular Textiles, every textile product will need a DPP in the next few years to share product data with stakeholders along the value chain. Brands worldwide are grappling with these requirements if they want to sell products in Europe - including those based in the US. With a growing focus on sustainability legislation in the US, as well, it's become clear that digitization, like in Europe, will play a critical role in closing the existing product data gap and preparing for impending national policies. The demand for digitization has never been more apparent in order to enable traceability, accountability, circular systems and customer transparency. With the increasing integration and use of technologies, such as QR codes, the US is poised to transform the way we exchange data within the apparel industry.

Today’s clothing label landscape

Physical clothing labels are the current global standard for sharing regulated information about textile products. You’re probably very familiar with the country of origin, fiber content and care labels you see as you get dressed each day. But contrary to belief, the “Made in”-type language that’s required on these labels doesn’t give the full story of a garment. In actuality, this “Made in” claim only tells the consumer where the garment was last processed - i.e. where it was assembled. On top of that, the required fiber contents don’t include non-fibrous or decorative materials if they don’t meet a specific percentage of product composition, despite perhaps being the most impactful materials on a garment from an environmental perspective. Additionally, a care label indicates the maximum treatment a garment can withstand several times over without being damaged - not what is necessarily recommended or what’s the most sustainable.

Adding more information to labels - like environmental impacts, certifications or material origin - would be beneficial to multiple stakeholders. But the amount of information that would be ideal to attach to a product for manufacturers, consumers and even third-party recyclers and resellers can lead to label creep - pages of labels that could be required in multiple languages in order to be sold in different countries. This would effectively make physical labels inefficient and far from user-friendly.

A call to modernize

The American Apparel and Footwear Association (AAFA) has taken the initiative to call upon legislators to modernize clothing label policies in the US. Their most recent campaign, #CutTheTape, is pushing for policymakers to allow brands to switch to digital solutions to replace outdated physical labels. Their goal is to provide required regulatory information that is simple, convenient and easy to access throughout an item’s entire lifecycle. The labels on clothes oftentimes are either cut or destroyed by the time it gets to resellers and recyclers, making it difficult for these stakeholders to process garments and materials. With digital labels like QR codes or NFCs that are linked to Digital IDs, access to data will be readily available, helping to close the gap of missing data. Not only will this enhance the type of sustainability information that is available to value chain holders, but also decrease the amount of label tape needed for current demand.

The law for product labels hasn’t changed since the 1960's - the AAFA argues that it’s time for an update.

The integration of digital label technology

QR codes are accelerating their way into the mainstream, becoming an accessible technology for public use, all catalyzed by the pandemic. Major apparel brands, such as Zalando, Ralph Lauren and Patagonia, are already transitioning to digital labels citing the benefits of long-term product connection.

“We can continue [the] conversation with customers beyond the point of purchase. So, five years down the road, when you’re ready to trade in your jacket, we can talk to you about how to do that. But also, are you interested in some of the events going on at a Patagonia store? Environmental efforts? Or a different jacket?”

- Jennifer Patrick, Global Head of Packaging and Branding, Patagonia

Research shows that customers that use hangtags to look for more specific product data are just as willing to scan a QR code to read information. A digital label acts as a gateway to having continuous connection with a product through events like resale, repair and reuse.

Even the revolutionary innovation to scan QR codes with a phone camera has been taken a step further. Apple’s most recent iOS17 update now includes a “Visual Look Up” tool that can decode laundry symbols on apparel products. This only shows the increasing demand for accessible product information and the ways in which technology can fulfill those needs.

Read on for more about the topic in our sources below:

- The Guardian - A garments label tells you where it was made but what does it reveal about its environmental impact?

- Ecotextile - Should QR codes replace clothing labels

- American Apparel & Footwear Association - AAFA Urges Congress to Allow Digital Labeling for Clothes

- Daily Mail - Game changing iOS17 feature revolutionize laundry

.webp)